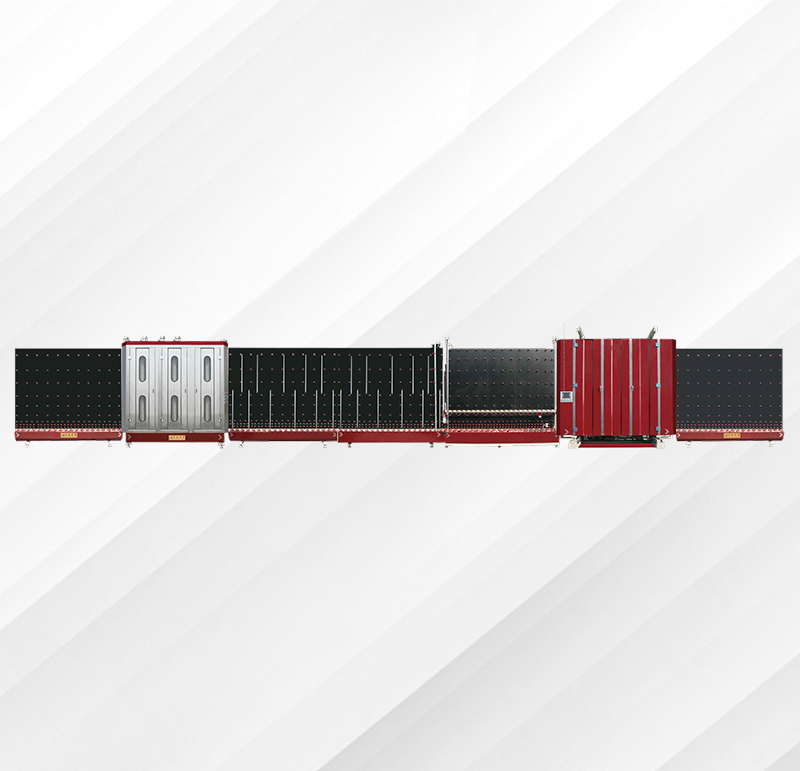

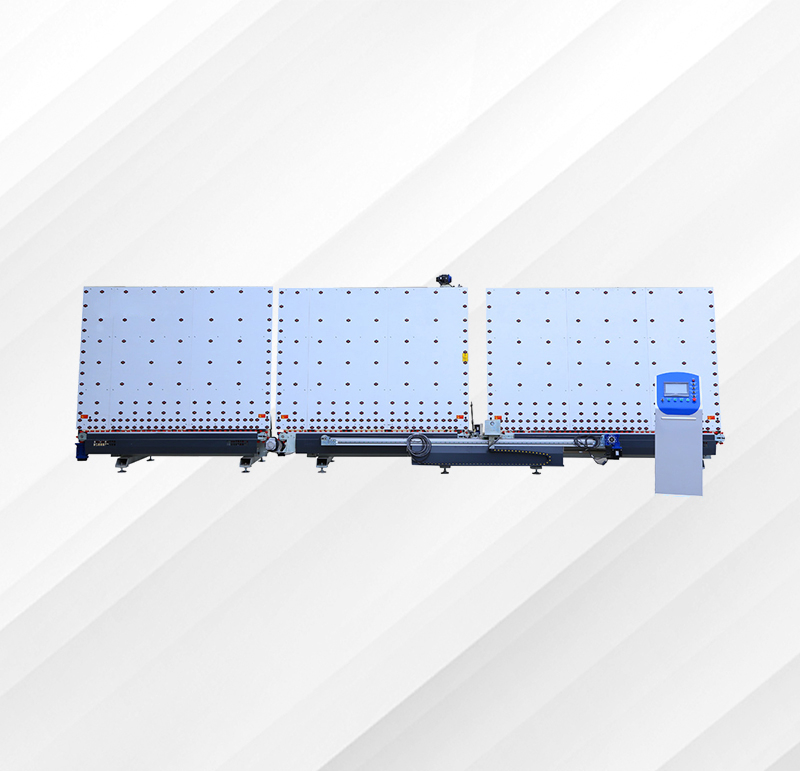

中空玻璃生產(chǎn)線設(shè)備特點(diǎn)

時(shí)間:2023-10-27 來源:http://www.leblanc.com.cn/ 發(fā)布人:昌盛機(jī)械

中空玻璃生產(chǎn)線設(shè)備實(shí)現(xiàn)自動(dòng)化生產(chǎn)的過程可以簡(jiǎn)述如下:

The process of automated production of insulating glass production line equipment can be summarized as follows:

原料倒入模具:將所需的原料倒入模具中,然后加熱熔化并凝固成液態(tài)。

Pouring raw materials into the mold: Pour the required raw materials into the mold, then heat, melt, and solidify into a liquid state.

加熱、成型和冷卻:使用人力或電動(dòng)工具進(jìn)行攪拌、成型和冷卻的工序。

Heating, forming, and cooling: The process of stirring, forming, and cooling using manual or electric tools.

泡沫材料混合:在成型階段,需要確保泡沫材料能夠均勻地混合在一起。

Foam material mixing: in the molding stage, it is necessary to ensure that foam materials can be mixed together evenly.

控制產(chǎn)品尺寸:這是為了確保產(chǎn)品的質(zhì)量。

Control product size: This is to ensure product quality.

自動(dòng)化控制系統(tǒng):中空玻璃成型機(jī)的控制系統(tǒng)主要完成對(duì)模組的加熱和冷卻、上下輥之間壓力的控制、模具的升降運(yùn)動(dòng)控制以及溫度的設(shè)定與控制等任務(wù)。

Automation control system: The control system of the insulating glass molding machine mainly completes tasks such as heating and cooling of the module, controlling the pressure between the upper and lower rollers, controlling the lifting motion of the mold, and setting and controlling the temperature.

噴涂系統(tǒng)控制:熱熔膠噴涂系統(tǒng)的控制系統(tǒng)則負(fù)責(zé)在高溫狀態(tài)下將液態(tài)硅酮結(jié)構(gòu)密封材料噴到兩塊平板中間形成氣室,并調(diào)節(jié)噴槍的壓力來實(shí)現(xiàn)氣室內(nèi)的壓力大小變化,以及根據(jù)設(shè)定的程序來調(diào)整出料的流量以及噴射的角度等。

Spraying system control: The control system of the hot melt adhesive spraying system is responsible for spraying liquid silicone structural sealing material into the middle of two flat plates to form an air chamber under high temperature conditions, adjusting the pressure of the spray gun to achieve pressure changes in the air chamber, and adjusting the discharge flow rate and spraying angle according to the set program.

實(shí)時(shí)監(jiān)控:在中控室可以實(shí)時(shí)監(jiān)控整個(gè)設(shè)備的運(yùn)行狀態(tài),如溫度顯示、電流顯示以及報(bào)警信息等。當(dāng)出現(xiàn)故障時(shí)可以通過中控室的屏幕查看具體的情況并進(jìn)行相應(yīng)的處理。

Real time monitoring: In the central control room, the operation status of the entire equipment can be monitored in real time, such as temperature display, current display, and alarm information. When a malfunction occurs, the specific situation can be viewed through the screen in the central control room and corresponding measures can be taken.

請(qǐng)注意,這是對(duì)中空玻璃生產(chǎn)線設(shè)備實(shí)現(xiàn)自動(dòng)化生產(chǎn)的一種簡(jiǎn)單化的描述,實(shí)際的過程可能更復(fù)雜,并涉及更多的步驟和細(xì)節(jié)。

Please note that this is a simplified description of the automated production of insulating glass production line equipment, and the actual process may be more complex and involve more steps and details.

相關(guān)新聞 moer+

- 探秘全自動(dòng)封膠線:高效生產(chǎn)的幕后英雄 2025/02/02

- 解鎖中空玻璃加工設(shè)備:開啟建筑節(jié)能新時(shí)代 2025/01/30

- 探秘中空玻璃生產(chǎn)線:高效生產(chǎn)背后的奧秘 2025/01/25

- 全自動(dòng)封膠線的應(yīng)用領(lǐng)域及發(fā)展趨勢(shì) 2025/01/22

- 中空玻璃全自動(dòng)封膠線一天能做多少平方的玻璃 2025/01/20

- 中空玻璃全自動(dòng)封膠線一天能做多少平方的玻璃 2025/01/15

- 中空玻璃全自動(dòng)封膠線的優(yōu)缺點(diǎn)是什么 2025/01/07

- 雙組份打膠機(jī)出花膠怎樣處理 2025/01/04

- 中空玻璃全自動(dòng)封膠線一天能做多少平方 2024/12/28

- 中空玻璃生產(chǎn)線一天能做多少平方 2024/12/23

相關(guān)產(chǎn)品 moer+

產(chǎn)品分類Product categories

產(chǎn)品分類Product categories

聯(lián)系我們Contact us

聯(lián)系我們Contact us

- 咨詢熱線:0531-85717458 13705446998

- 公司地址: 山東省德州市齊河安頭鄉(xiāng)企巢工業(yè)園

- 掃碼聯(lián)系我們:

當(dāng)前位置:

當(dāng)前位置: